Micro Hole Metal Etching One-Stop Processing Service

As an experienced precision etched mesh manufacturer, XINHAISEN provides high-accuracy metal etching solutions using photo chemical etching technology. Our capabilities cover flat etched mesh as well as forming and welding, supporting demanding industrial and coffee equipment applications.

Flat Etched Mesh & Secondary Processing Capabilities

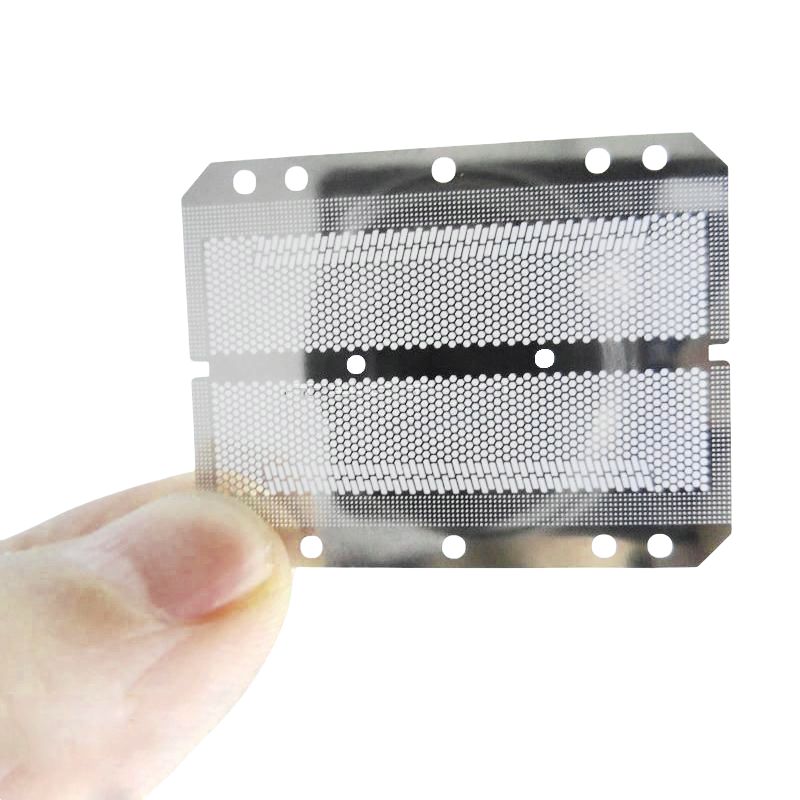

Flat Metal Etched Mesh

High-precision flat etched mesh in stainless steel and other alloys.

Stamping & Forming

Etched mesh can be stamped or formed into 3D structures such as domed or curved parts.

Welding & Assembly

We provide welding and assembly services for multi-layer or integrated mesh components, enabling functional finished parts.

High Precision Micro Hole Etching (Minimum 0.02mm)

Our chemical etching process enables a minimum hole diameter of 0.02mm, delivering:

- Uniform and consistent apertures

- Burr-free and smooth edges

- No mechanical stress or material deformation

This makes metal etched mesh ideal for micro filtration, flow distribution, and precision functional parts.

True 1:1 Aperture Accuracy

We support true 1:1 aperture etching, accurately reproducing customer drawings without scaling errors. Complex hole patterns, high-density apertures, and customized open areas can be precisely achieved.

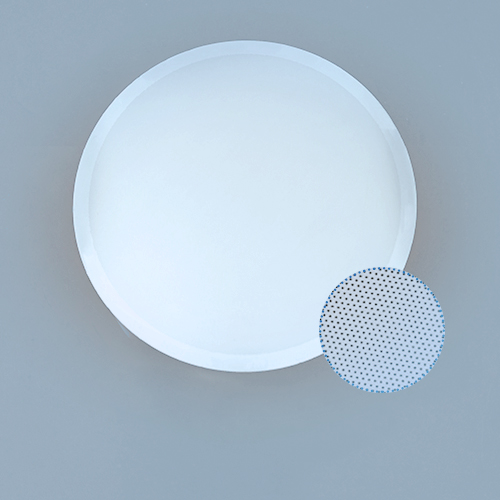

Typical Applications of Precision Etched Mesh

Our etched mesh products are widely used in industrial and consumer applications, including:

- Coffee machine shower screens

- Coffee filter mesh

- Precision filtration components

- Flow distribution and control parts

In coffee equipment, etched mesh ensures even water distribution, stable pressure, and consistent extraction quality.

One-Stop Metal Etching Manufacturing Service

From design review to final delivery, we offer a one-stop precision manufacturing service, including:

- Material selection support

- Drawing evaluation and optimization

- Chemical etching

- Forming, welding, and surface treatment

We support both prototyping and mass production for global customers.

Why Choose Our Precision Etched Mesh

- Minimum hole size: 0.02mm

- Accurate 1:1 aperture etching

- Burr-free, stress-free processing

- Flat etching + forming + welding in-house

- Reliable quality for industrial applications