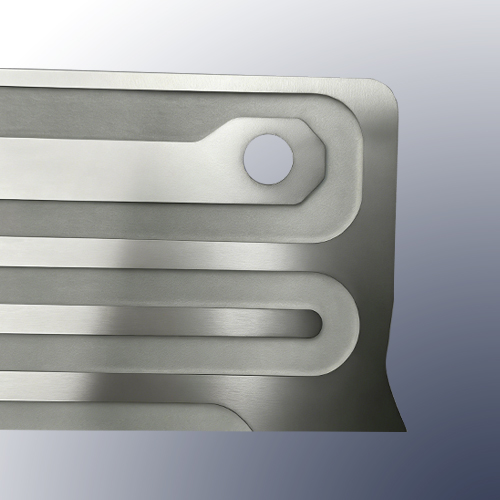

Ethed Liquid Cooling Cold Plate

In many advanced applications, micro-scale heating management requires precise and uniform heat generation at localized areas. Etched liquid cooling cold plate is ideal micro-heating elements that provide accurate, repeatable,and evenly distributed heat, making them essential for electronics, medical devices, semiconductor equipment, and precision industrial processes.

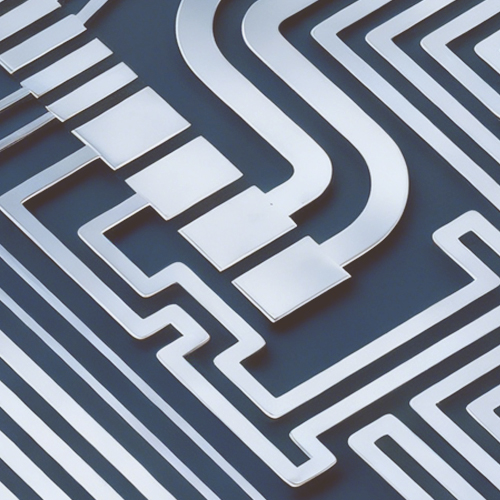

Using photochemical etching fabricates foil heaters allow complex resistance patterns and micro-structures to be formed directly in metal foil. This process ensures high dimensional accuracy, excllent repeatability, and superior thermal performance, enabling reliable operation in demanding thermal environments.

Etched Liquid Cooling Cold Plate Advantages

Technical Specifications

Liquid cooling cold plates are typically manufactured from materials selected for their thermal conductivity, corrosion resistance, mechanical strength, and cost-effectiveness. The most commonly used materials include aluminum, copper and stainless steel, depending on application requirements.

Xinhaisen provides One-stop processing service, not just chemical etching processing. To enhance performance and durability, cold plates can be supplied with surface treatments such as anodizing, nickel plating, or anti-corrosion coatings.

Csutom liquid Cooling Cold Plate Solution & Manufacturing

We provide cutomized liquid cooling cold plate tailored to customer requirements, from design evaluation and thermal simulation to prototyping and massprodution. Our etched foil heaters are manufactured for consistency, reliability and performance in virous applications, such as High-power electronics cooling, Laser systems and IGBT modules, Battery systems and precision instruments.

Chemical Etching Benefits

Burr-Free

Unlike traditional mechanical processing, etching does not produce burrs, ensuring that the component surfaces are smooth and flat, thereby enhancing the quality and performance of the components.

Long Lifespan

Due to the high precision, smooth surfaces, and stress-free nature of etched components, they generally have a longer lifespan.

Flexibility in Design/Customization:

Etching processing allows for the realization of complex and intricate designs, greatly enhancing the flexibility in component design and customization, and enabling quick responses to specific customer requirements.

No High Mold Costs

Etching processing does not require the creation of expensive molds, significantly reducing initial investment costs. This makes it particularly suitable for small batch production and rapid prototyping.

Stay Connected with Us

Let’s Create Together

Connect with us to explore how we can make your vision a reality. Join us in shaping the future.