Automotive Photochemical Machining & Precision Metal Etching

With the continuous development of the automotive industry towards electrification, intelligence, and lightweighting, automotive photochemical machining technology is becoming an important supporting process in precision metal manufacturing.

Hysenetch focuses on precision photochemical etching manufacturing and metal structural part processing in the automotive field. It widely serves sectors such as fuel systems, electronic modules, sensors, battery components, and new – energy vehicle parts, providing customers with metal manufacturing solutions featuring high precision, high cleanliness, lightweight, and stress – free characteristics.

The Vital Role of Automotive Photochemical machining

Automotive Photochemical machining (PCM), with its high precision, low deformation, and flexibility, is widely applied in the manufacturing of core metal components in the automotive industry.

—— High Precision and Capability for Complex Structures ——

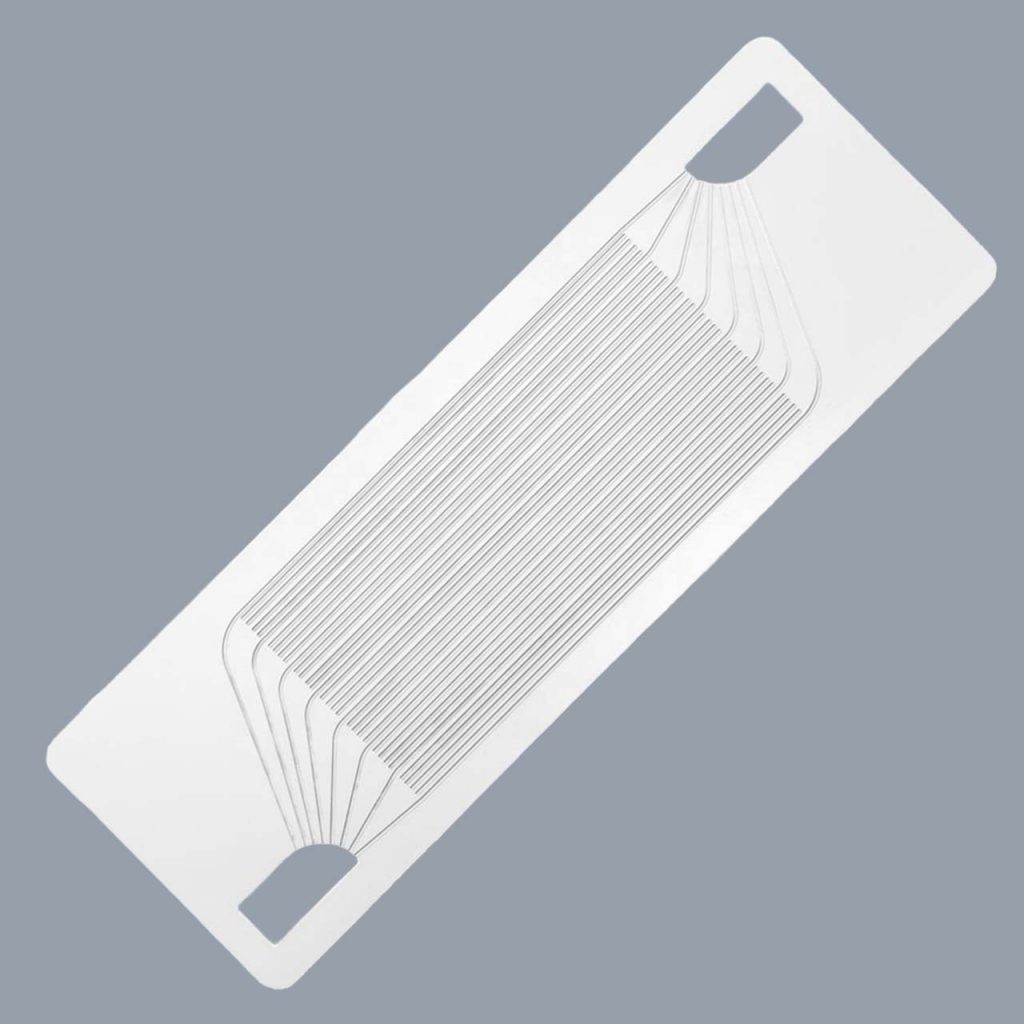

Hysenetch’s automotive photochemical machining can achieve precision control within ±0.005mm. It can manufacture complex geometric shapes without generating mechanical stress, thus meeting the design requirements. This technology is highly suitable for high- precision automotive parts such as sensor films, motor stator sheets, and fuel injector screens.

—— Lightweighting and Energy Efficiency Improvement ——

In electric and hybrid vehicles, weight reduction directly impacts driving range and energy efficiency.

Photochemical etching manufacturing can reduce the amount of metal used, achieving lightweight parts while mantaining strength and electrical conductivity. It is an ideal solution for structural components of new – energy vehicles.

—— Cost-effective and Rapid lteration ——

Compared with traditional stamping or die – processing, photochemical etching does not require expensive dies. With its flexible manufacturing process, it is suitable for sample development, small – batch trial production, and medium – volume production. This provides automotive manufacturers with a faster development response speed.

Advantages in Automotive Photochemical machining manufacturing

Complete Photochemical Etching Production System

Hysenetch has a fully – automated production line that covers photomask production, exposure and development, etching control, as well as inspection and packaging. This ensures the stability and consistency of every automotive metal – etched component.

Multi – material Adaptability

We can process a variety of automotive metal materials, including stainless steel, copper, nickel, aluminum, titanium, and special alloys.Meanwhile, we offer post – treatment processes such as electroplating, passivation, oxidation, coating, and precision cleaning to enhance the corrosion resistance and appearance quality of the parts.

Automotive – grade Quality Control System

All production processes comply with the IATF 16949 and ISO 9001 standards.Each production step undergoes strict inspection and data traceability to ensure that products meet the quality requirements of global OEMs (Original Equipment Manufacturers) and Tier 1 suppliers.

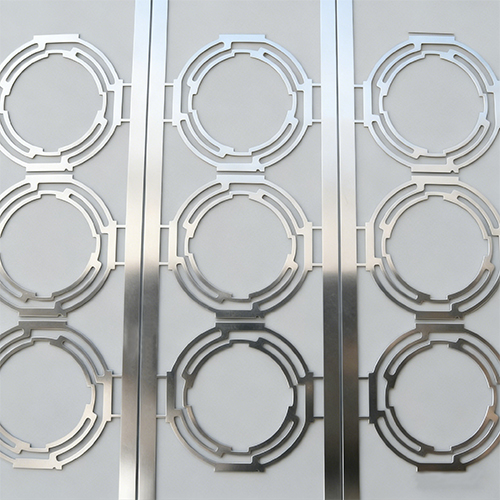

Typical Applications of Automotive Photochemical Machining Components

Hysenetch’s photochemical etching technology is widely used in:

- Fuel and Injection Systems: Precision filters, nozzle plates, flow control plates

- Battery Systems and New – energy Vehicles: Current busbars, connection tabs, heat dissipation guide plates

- Sensors and Electronic Systems: Sensitive diaphragms, signal shielding covers, electromagnetic interference shielding parts

- Engine and Exhaust Systems: Gaskets, seal plates, guide plates

- Autonomous Driving and Safety Systems: Camera housings, circuit interface components, micro – structure filter sheets

These high – precision parts manufactured through automotive photochemical etching processing help automotive manufacturers improve system reliability, stability, and energy efficiency performance.

Why Choose Hysenetch?

Over 13+ years of precision metal manufacturing experience: Specializing in the production of high – precision metal components for the aerospace, automotive, and electronics industries.

Rapid prototyping and flexible production capabilities: No need for molds, short development cycle, suitable for new product verification and medium – volume production.

Global customers and delivery system: Providing international delivery and customized packaging, supporting global automotive supply chain collaboration.

Engineering technical support: Offering “Design for Etching” services to assist customers in optimizing structure and cost during the design phase.

Strict confidentiality mechanism: Securely encrypting and internally isolating customers’ drawings, formulas, and parameter information.

Contact Us to Start Your Automotive Etching Manufacturing Project

Hysenetch is committed to providing innovative, precise, and sustainable metal etching solutions for global automotive manufacturers.Whether you need to develop battery connectors for new – energy vehicles or high – precision sensor structural components, we can provide fast and reliable manufacturing support.