Metal Etching in BMIC (Battery Management Integrated Circuit) Market

Embrace the future of BMIC manufacturing with metal etching – where precision meets performance.

The battery management integrated circuit (BMIC) market is experiencing unprecedented growth, fueled by the demand for advanced energy storage and management systems. At the core of this innovation lies metal chemical etching, a cutting-edge manufacturing process that enables the productiong of high-precision components essential for BMICs. We will delve into it together how metal etching in the BMIC market is driving efficiency, scalability, and performance.

Why Metal Etching is Critical for BMIC Components?

Metal photo etching , a highly specialized and advanced manufacturing technique, has found extensive applications in the fabrication of pivotal components within two of the most technologically advanced industries: batteries and integrated circuits.

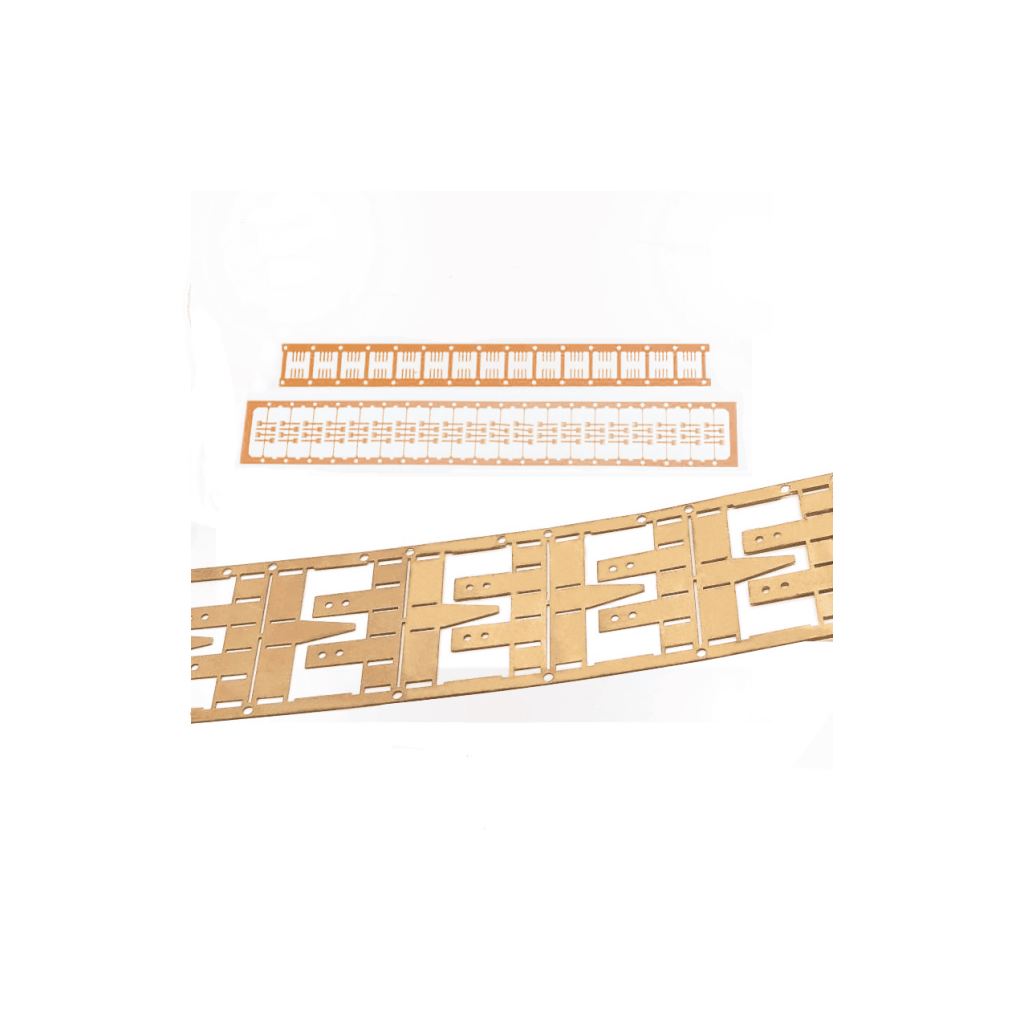

In the realm of integrated circuits, especially in the context of Ball Grid Array (BGA) and other types of Multichip Integrated Circuits (BMICs), metal etching plays a critical role. It is employed to produce several key elements that are the linchpins of the circuit’s functionality. Lead frames, for instance, serve as the mechanical and electrical interface between the integrated circuit die and the external world. Through the metal photo – etching process, these lead frames are crafted with meticulous precision. Each lead is precisely shaped and positioned to ensure optimal electrical conductivity and mechanical stability.

Interconnects, another vital component, are also manufactured using this technique. These are the pathways that allow the flow of electrical signals between different parts of the integrated circuit. The photo etching process enables the creation of interconnects with extremely fine – tuned dimensions, minimizing signal loss and maximizing the speed of data transfer. Spring connects, which provide flexible electrical connections, are produced with a level of precision that ensures reliable contact even under various mechanical stresses. They are designed to maintain consistent electrical contact, whether in static or dynamic conditions within the circuit.

Bonding pads, where the wires are attached to connect the integrated circuit die to the lead frames or other components, are also fabricated through metal photo etching. The pads need to have a smooth and flat surface to ensure a strong and reliable bond. The photo etching process can achieve this with micron – level accuracy, guaranteeing the integrity of the electrical connections and the overall performance of the integrated circuit.

When it comes to batteries, metal etching is equally essential. Current collectors are a prime example. These are the components that collect and transfer the electric current generated within the battery. They need to have high electrical conductivity and good mechanical properties. Metal photo etching allows for the creation of current collectors with precisely designed geometries. The process can produce complex patterns on the current collectors, enhancing their surface area for better contact with the active materials in the battery. This, in turn, improves the efficiency of charge and discharge processes, leading to more efficient energy transfer.

Electrodes, another crucial part of the battery, are also manufactured using metal etching. Electrodes are responsible for facilitating the electrochemical reactions that occur within the battery. The metal etching process can precisely control the shape, size, and porosity of the electrodes. This is important as it affects the reaction kinetics and the overall performance of the battery. By achieving micron – level precision in electrode manufacturing, metal chemical etching enables the production of batteries with higher energy density, longer lifespan, and better charge – discharge efficiency.

The ability to achieve micron – level precision is what truly sets metal chemical etching apart and makes it an indispensable technology for manufacturing these intricate and highly – specialized parts in both batteries and integrated circuits. It allows for the production of components with the exact specifications required, ensuring the reliability, performance, and miniaturization of modern – day electronic devices. Whether it’s the need for ultra – fine electrical connections in integrated circuits or the precise control of electrode properties in batteries, metal photo etching continues to drive innovation in these industries.

Key Advantages of Metal Etching in BMIC Manufacturing

As the battery management integrated circuit market expands, the need for reliable, high-performance components grows. Photochemical etching addresses these challenges by offering a cost-effective, scalable, and precise manufacturing solution. Its ability to produce complex, high-quality parts ensures that BMICs can meet the evolving demands of energy storage and management systems.

Metal etching is a game-changer in the BMIC market, enabling the production of components that are both precise and efficient. By leveraging this advanced manufacturing process, Hysen can offer innovative solutions for energy management.