Aluminum Etching

Precision Chemical Etching Services on aluminum for Custom Components

Aluminum Etching Manufacturer

As a leading etching specialist with over 13 years of experience, we master the art and science of aluminum chemical etching, enabling us to produce high-precision components for various industries. Our certified processes, backed by ISO9001, ISO14001, IATF 16949, and National Military Standards, deliver unparalleled precision and quality for industries demanding the highest reliability.

Our aluminum photo chemical etching service is a superior solution for manufacturing complex and delicate custom aluminum etching parts. Unlike traditional methods like laser cutting or stamping, chemical etching does not introduce mechanical stresses, burrs, or heat-affected zones. This makes it ideal for producing burr-free, stress-free components with perfect consistency and without altering the material properties of the aluminum.

Which industries is Aluminum Photo Chemical Etching used to?

We specialize in producing high-precision custom aluminum etching components for a wide range of applications, such like Aerospace, Automotive, Electronics etc.

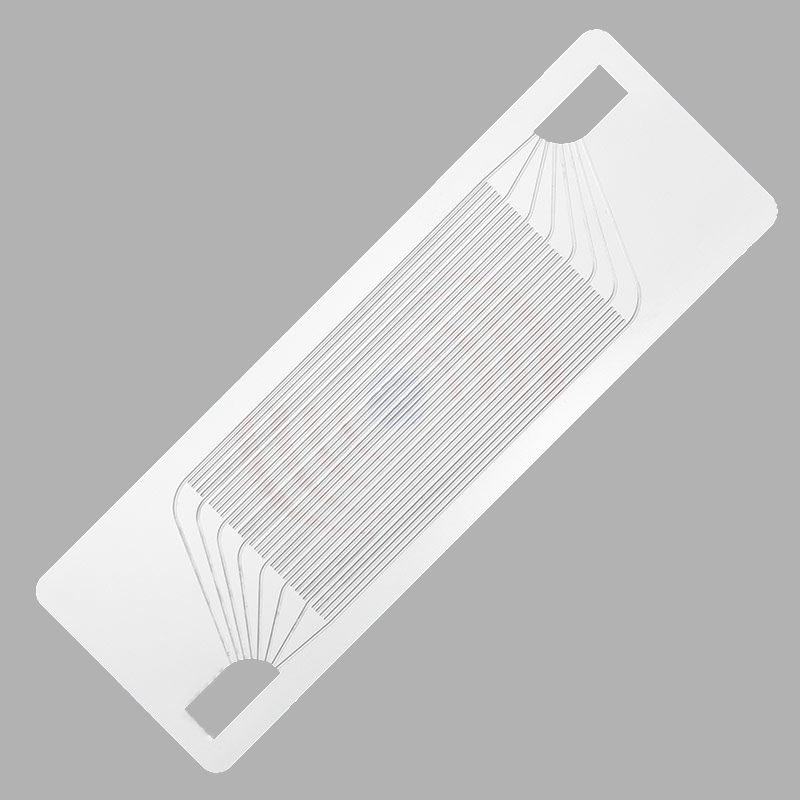

Aluminum Etched Parts

- RFI/EMI shielding lids and gaskets

- Flexible Heater Elements

- Encoder discs and springs

- Nameplates and labels

- Masks and shims

- Speaker grills

The precision aluminum chemical etching machining process allows for incredibly fine feature details, complex geometries, and rapid prototyping. Whether you need prototypes in days or high-volume production runs, our flexible etching lines can accommodate your needs. We work with various aluminum grades, ensuring we meet your specific requirements for conductivity, strength, and corrosion resistance.

Benefits of Aluminum Chemical Etching

Why Choose Our Custom Aluminum Etching Services?

- 13+ Years of Expertise: Deep knowledge in metallurgy and etching techniques.

- Multi-Industry Certified: Compliant with automotive (IATF 16949) and defense standards.

- High Precision & Complexity: Achieve intricate designs and tight tolerances effortlessly.

- Fast Turnaround: From design to delivery, we ensure speed without compromising quality.

If you are looking for a reliable partner for your custom aluminum etching parts, trust our proven expertise. Contact us today to discuss your project and receive a competitive quote.

Choose us, you gain a trusted and high-quality partner!