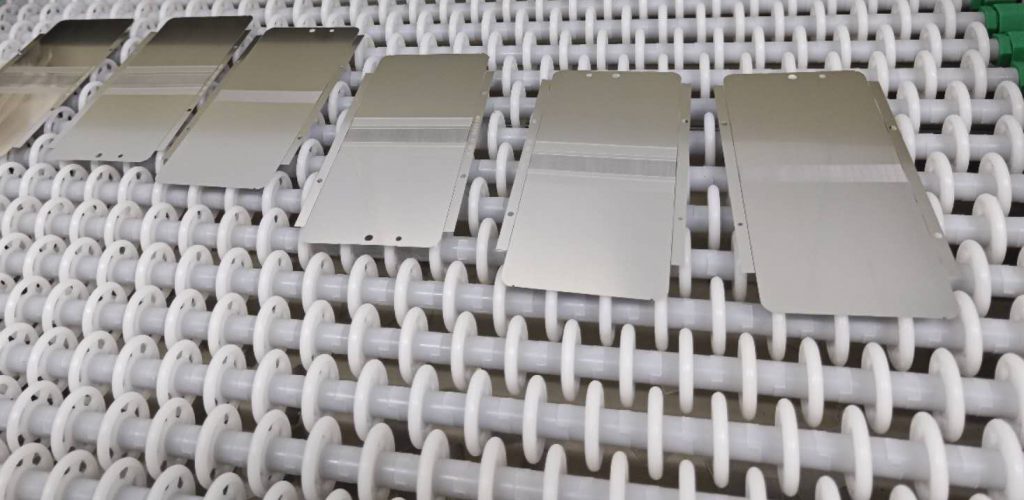

TITANIUM etching

Titanium and Titanium Alloy Chemical Etching Manufacturing

Titanium Etching Processing Solutions

In the field of high – performance material manufacturing, titanium etching processing technology is becoming a key manufacturing process in the aerospace, medical, electronics, and new energy industries. Titanium and its alloys are characterized by low weight, high strength, and excellent corrosion resistance. However, they are also known for their high processing difficulty and low efficiency in traditional mechanical cutting. Hysenetch provides customers with high – precision, stress – free, and mass – producible titanium part processing solutions through Photochemical Machining (PCM) technology.

Technical Advantages of Photochemical Etching in Titanium Processing

Non – Contact Processing to Avoid Stress Deformation

Titanium metal has high hardness and toughness. Traditional CNC or stamping processing is likely to cause micro – deformation and tool wear. Photochemical etching is a non – contact process. It selectively dissolves the metal surface through chemical reactions to achieve the manufacture of high – precision patterns and micro – structures. Without the action of mechanical force, it effectively avoids deformation and residual stress.

High Precision and Realization of Complex Geometric Shapes

Hysenetch’s titanium etching processing can achieve a line – width precision of ±0.02mm. It can process complex structures such as micro – holes, fine grooves, meshes, and markings. It is widely used in the manufacture of support sheets for medical implants, electronic filters, sensor frames, and thin sheets in aerospace systems.

High Precision and Realization of Complex Geometric Shapes

Photochemical etching is different from laser cutting or stamping, and it does not generate a heat – affected zone or burrs. The edges of the etched titanium sheets are neat, which is suitable for subsequent surface treatment processes such as welding, electroplating, oxidation, and polishing.

Typical Application Industries of Titanium Etching Processing

Aerospace and Aviation

In the aerospace field, the lightweight and corrosion – resistant properties of titanium alloys are of great importance. Titanium sheet structural components manufactured by photochemical etching are commonly used in sensor brackets, thermal insulation layers, heat – dissipation meshes, and fuel system filters.

Medical Devices and Implantable Devices

The biocompatibility of titanium makes it the first – choice material for medical devices and implantable devices. Hysenetch’s titanium etching technology can process products such as medical mesh sheets, electrode plates, conductive brackets, and catheter filters, ensuring stable dimensions, no pollution, and smooth edges.

Electronics and Semiconductors

Titanium also plays an important role in semiconductors, MEMS, and electronic heat – dissipation components. Titanium – etched parts are widely used in the manufacture of IC packaging brackets, micro – heat sinks, RF shielding parts, and high – purity conductive thin sheets.

Hydrogen Energy and Electrochemical Fields

Titanium has excellent corrosion resistance and electrical conductivity and is an important material for systems such as hydrogen fuel cells and ion – exchange membrane electrolyzers. Hysenetch can provide customized photochemical etching services for titanium metal electrodes, microporous diffusion layers, and catalytic support meshes.

Hysenetch‘s Titanium Etching Manufacturing Capabilities

- Processable thickness range: 0.02mm – 1.0mm

- Maximum etched area: 2400mm × 700mm

- Etching precision: ±0.02mm

- Minimum aperture: 0.1mm

- Material types: Pure titanium, TA2, TC4, Ti – 6Al – 4V, Ti – 0.3Mo – 0.8Ni, Ti – Fe alloy, etc.

Hysenetch has a complete dedicated titanium etching process system. From mask design, exposure and development, etching control to inspection and packaging, all processes are completed in a dust – free environment to ensure product purity and consistency.

Quality and Inspection

We strictly follow ISO 9001 and RoHS standards. Titanium – etched parts go through:

- Optical measurement and microscopic inspection

- Metallographic cross – section analysis

- Surface flatness and thickness uniformity testing

- Corrosion rate and surface residue detection

Each batch of titanium – etched parts has a unique traceability number, enabling full – process control and data querying.

Quality and Inspection

- 20 years of experience in metal photochemical etching: With deep accumulations in the processing of materials such as titanium, stainless steel, nickel, and copper.

- Dedicated titanium etching formula and hydrogen embrittlement prevention treatment: The special chemical system ensures a smooth etched surface and no hydrogen adsorption.

- Rapid prototyping and flexible small – batch manufacturing: No need for molds, suitable for quick verification in the R & D stage.

- A trusted supplier for global customers: Long – term cooperative customers are from high – end manufacturing enterprises in Europe, North America, and Asia.

- Complete integrated post – treatment capabilities: Including anodizing, surface passivation, electropolishing, etc.

Contact Us to Customize Titanium Etching Processing Solutions

If you are looking for a photochemical etching manufacturing partner for titanium and its alloys, Hysenetch will provide you with the best solutions with titanium etching service for high – precision technology, strict quality control, and quick response.