Etched Speaker Grilles: Precision, Aesthetics, and Uncompromised Acoustics

When delving into the intricate realm of engineering high – fidelity audio equipment, the significance of every single component cannot be overstated. Among these components, the speaker grille holds a particularly crucial position. Its role is two – fold: not only does it have to safeguard the delicate speaker driver from potential damage, be it from physical impact or environmental factors, but it must also do so while imposing the least possible interference on the sound waves emanating from the driver. This delicate balance is what makes the design and manufacturing of speaker grilles a highly specialized task.

This is precisely where photo – chemical etching truly shines, emerging as the preeminent manufacturing process for crafting premium speaker grilles. Traditional manufacturing methods like punching or laser cutting come with their own set of limitations. Punching, for instance, often results in the formation of burrs along the edges of the cut. These burrs not only affect the aesthetic appeal of the grille but can also cause unwanted reflections or disruptions to the sound waves. Additionally, punching subjects the material to mechanical stress, which might potentially distort the shape of the grille or compromise its structural integrity over time.

Laser cutting, although precise in many aspects, can sometimes introduce heat – affected zones around the cut edges. This heat can alter the material properties, especially in sensitive materials used in high – end audio equipment, and may also lead to micro – cracks or other imperfections.

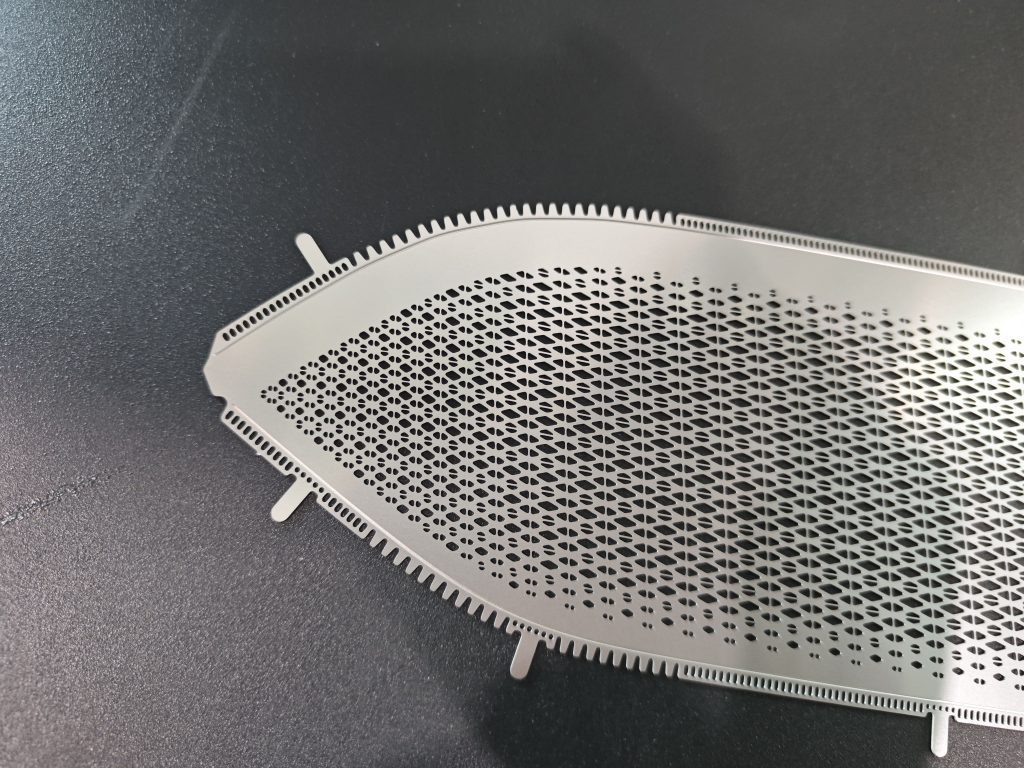

In stark contrast, photo – chemical etching is a burr – free and stress – free subtractive process. It operates by leveraging digital tooling, which allows for highly accurate and detailed designs to be transferred onto the material. Chemicals are then used to selectively and precisely remove the unwanted material, resulting in the creation of exceptionally clean and accurate openings. This meticulous process ensures that the final speaker grille not only looks sleek and professional but also performs optimally, enabling the sound to pass through with minimal distortion and maximum fidelity.

Key Benefits of Photo-Chemical Etched Speaker Grilles:

- Optimal Acoustic Performance: The process produces perfectly smooth, burr-free holes with no mechanical stress or heat-affected zones. This precision ensures minimal sound distortion and airflow resistance, allowing for true-to-source audio reproduction.

- Unlimited Design Flexibility: From complex geometric patterns to custom brand logos, photo-chemical etching can achieve virtually any aperture design without the cost of hard tooling. This allows for unique aesthetic differentiation for your speaker grilles.

- Exceptional Consistency and Durability: Every photo-chemical etched speaker grille is identical, ensuring uniform quality across high-volume production runs. The etched patterns are integral to the material, making them highly durable and resistant to wear.

- Cost-Effectiveness for Complex Designs: For intricate or custom designs, photo-chemical etching is significantly more economical than laser cutting or stamping, especially during prototyping and small to medium batches.

Applications:

This technology is ideal for manufacturing high-performance speaker grilles for luxury headphones, home audio systems, automotive sound systems, professional studio monitors, and consumer electronics.

In conclusion, for brands that refuse to compromise on sound quality or design, photo-chemical etched speaker grilles represent the ideal solution. They merge flawless functionality with striking aesthetics, defining the standard for modern audio equipment.

Xinhaisen founded in 2012, specializes in manufacturing high-precision metal parts. We have passed ISO9001, ISO14001, IATF16949 and Military standard certifications.

Our main process techniques are photochemical etching and precision stamping processing.

We can process over 30 types of metal materials, from classic stainless steel, copper, and aluminum to high-performance titanium alloy, nickel alloy, and Inconel alloy. This allows us to provide key metal components that integrate exceptional performance, superior corrosion resistance, and extreme lightweight.