Why Choose Hysenetch

- Ultra‑fine photochemical etching with tight tolerances

- Multi‑material capability: Stainless steel, Titanium, Copper, Nickel, Aluminum

- Ideal for thin, micro, complex metal components

- Rapid prototyping & mass production

- No burrs, no mechanical stress, high repeatability

- Engineering support & DFM service

- Fast lead time & competitive pricing

- Export‑ready for US & EU clients

Industries & Applications

- Aerospace components

- Medical devices

- Automotive sensors & shims

- Electronics & micro metal parts

- Precision filters & meshes

- Battery components

- Optical & instrumentation parts

Metal Materials We Support

- Stainless Steel

- Copper

- Titanium

- Nickel

- Aluminum

Full-Service PhotoChemical Etching Manufacturer

Hysenetch provides full-process support from design verification to final production:

- Design review & engineering support

- Rapid prototyping

- 6 photochemical etching production lines

- Precision stamping (optional)

- Surface finishing & secondary processing

- Quality inspection & packaging for export

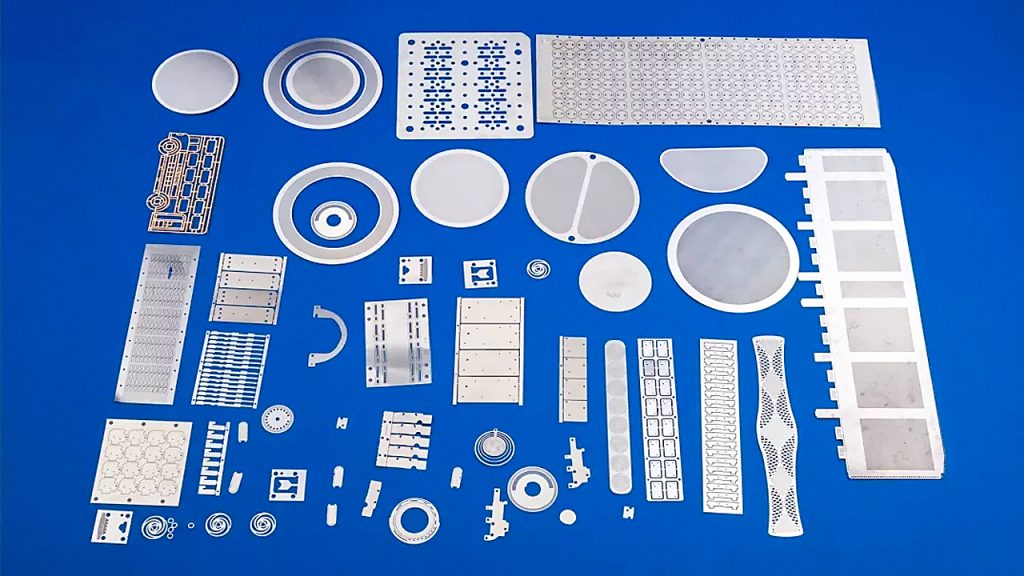

Typical Products We Made

Hysenetch provides custom metal parts machining service

- Bipolar Plates

- Micro Mesh & filters

- Micro metal springs

- Metal Shims & washers

- EMI shielding parts

- Encoder discs

- Custom micro components

Certifications

We are fully certified to international quality and environmental standards.

ISO 9001 • ISO 14001 • IATF 16949