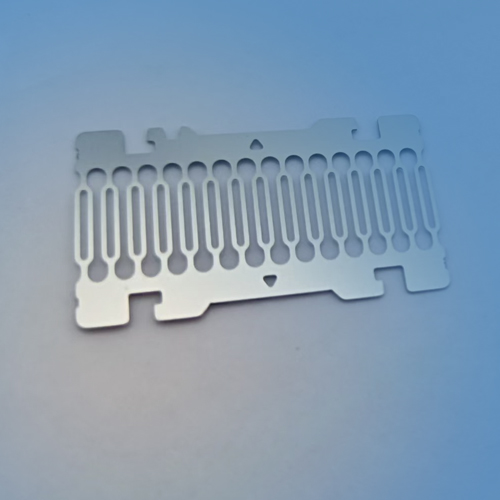

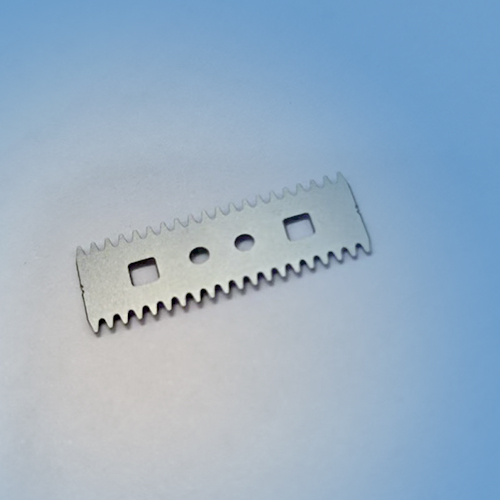

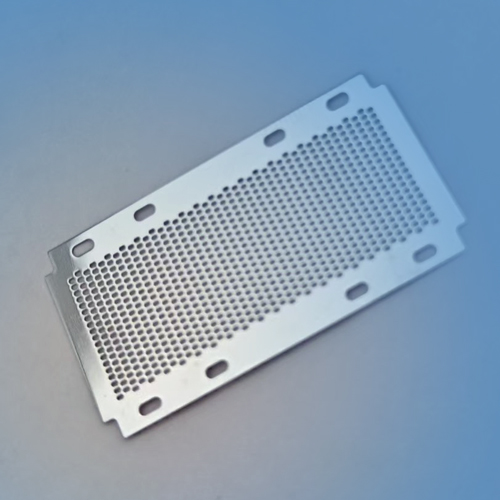

Eetched Razor Blades

Razor Blades Popular Processing Technologies

Modern razor blades are crafted through stamping, laser cutting, grinding, and photochemical etching. While traditional methods like stamping suit high-volume production, theystruggle with complex geometries. Laser cutting offers precision but risks thermal distortion. Incontrast, photochemical etching delivers unmatched versatility for intricate patterns without compromising blade integrity.

Why choose photochemical etching processing for razor blades?

Photochemical etching excels in producing etched razor blades with micron-level accuracy. This process uses chemical solutions to selectively remove material, ensuring burr-free edges and stress-free surfaces.

Key advantages include:

Why choose Hysen?