copper chemical etching

Harnessing the Power of Copper Chemical Etching, Manufacture Precision and Versatility Metal Components

What’s copper chemical etching?

Copper chemical etching is a sophisticated manufacturing process that leverages chemical solutions to selectively remove material from copper and copper alloys. This technique is pivotal in creating intricate designs and precise components that are essential in varous high-tech industries. By chemical etching, Hysen can unlock a plethora of applications and benefits, ensuring superior product quality and performance.

Main Products of Copper Chemical Etching

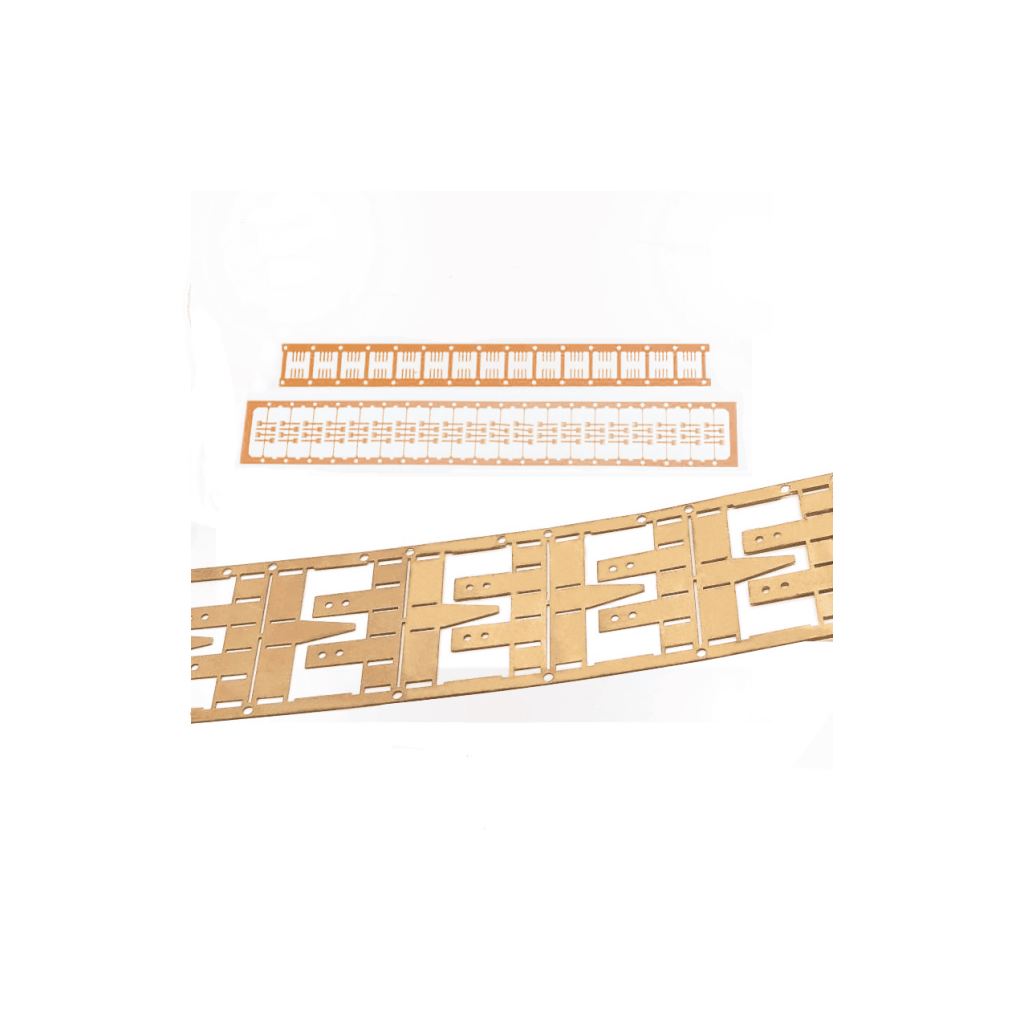

Copper and its alloys are popular materials for etching due to their excellent electrical conductivity, corrosion resistance, and malleability. The main products fabricated through copper etching include printed circuit boards (PCBs), precision metal components used in aerospace and medical devices, connectors, lead frames and decorative copper artworks. These products benefit from the high precision and repeatability of the etching process, which ensures consistent quality across large production runs.

Applications of Copper Etched Products

Copper etched products find their applications in several key sectors. In electronics, they are crucial for the functionality of circuit boards and microchips. The aerospace industry utilizes these components for their lightweight and durability while the medical field relies on them for intricate surgical instruments and implants. Furthermore, the aesthetic appeal of etched copper is exploited in architectural elements and jewelry.

Advantages of Etching Copper and Copper Alloys

The advantages of using copper etching are manifold. Firstly, it allows for high precision and complexity in designs without inducing mechanical stress or deformation. Secondly, it is cost-effective for both prototyping and mass production, as it eliminates the need for expensive tooling. Additionally, the process is highly scalable and can be easily adjusted to meet varying production demands.

Challenges and Considerations in Copper Etching

Despite its many benefits, copper etching does present certain challenges. The process reqires careful control of chemical concentrations and etching times to prevent issues such as over-etching or under-etching. Environmental and safety considerations are also paramount, as the chemicals used can be hazardous. Proper waste management and adherence to safety protocols are essential to mitigate these risks.

Why choose Hysen?

Our company has over a decade of extensive experience in copper etching processing, with mature and refined techniques. The factory is certified under the ISO9001 Quality Management System and the ISO14001 Environmental Management System, ensuring stable product quality and high standards of environmental safety. We are committed to providing high-quality copper chemical etching services to our clients while strictly adhering to environmental and safety regulations, contributing to sustainable development.

In conclusion, copper chemical etching is a versatile and efficient manufacturing method for producing high-quality copper and copper alloy components. Its a bility to create precise and complex parts makes it indispensable across various industries. However, Successful implementation requires a deep understanding of process parameters and a commitment to safety and environmental standards.